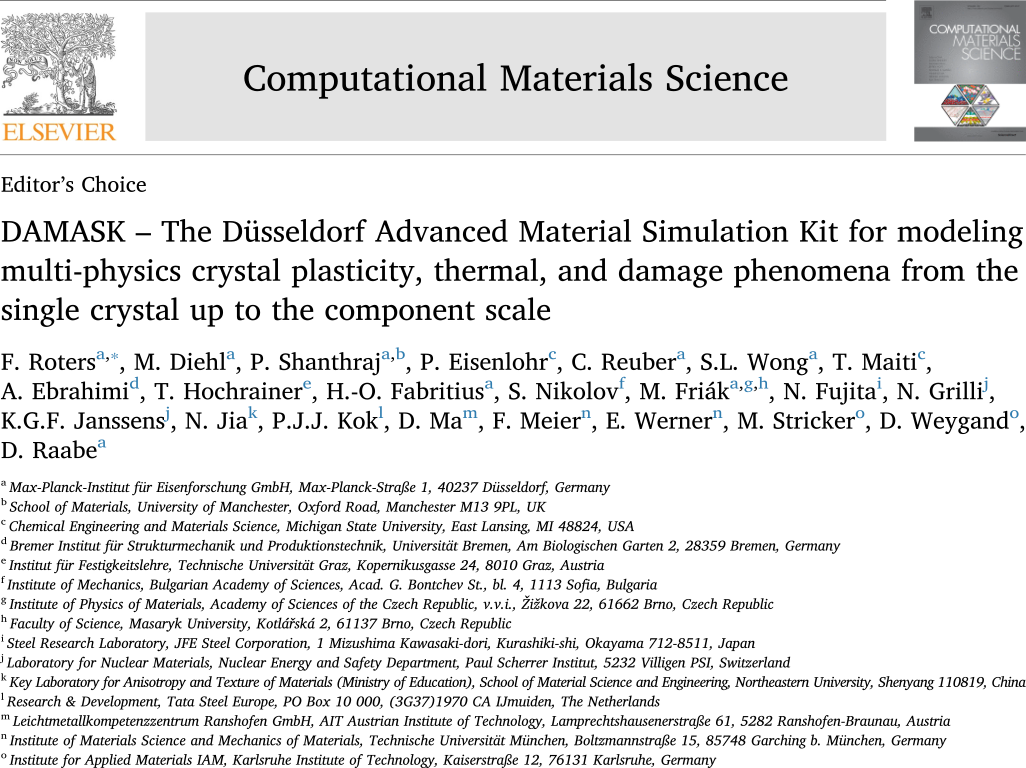

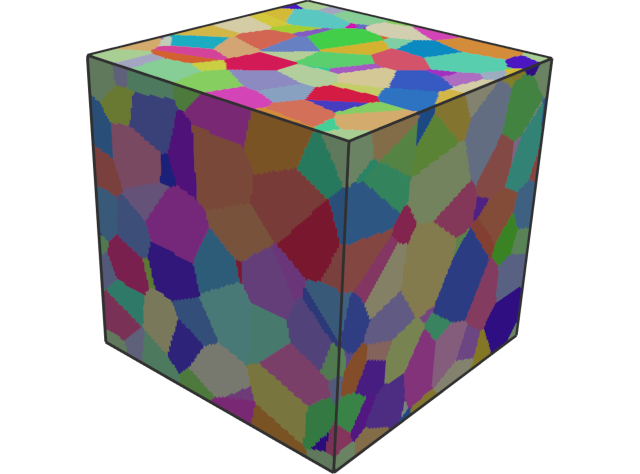

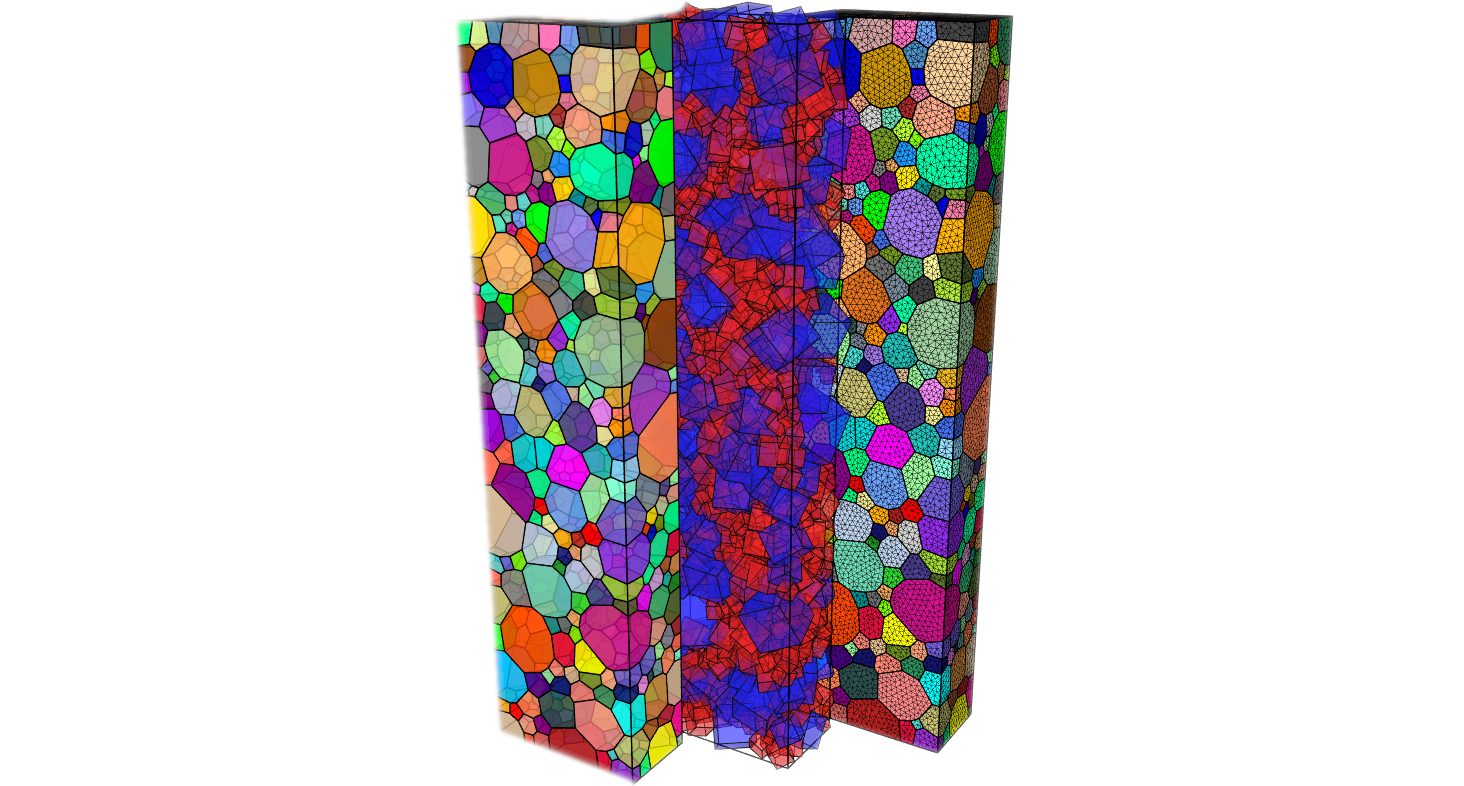

DAMASK is a unified multi-physics crystal plasticity simulation package. The solution of continuum mechanical boundary value problems requires a constitutive response that connects deformation and stress at each material point. This problem is solved in DAMASK on the basis of crystal plasticity using a variety of constitutive models and homogenization approaches. However, treating mechanics in isolation is no longer sufficient to study emergent advanced high-strength materials. In these materials, deformation happens interrelated with displacive phase transformation, significant heating, and potential damage evolution. Therefore, DAMASK is capable of handling multi-physics problems. Following a modular approach, additional field equations are solved in a fully coupled way using a staggered approach.

Features#

Usage Examples#

DAMASK comes with a Python 3 library for pre- and post-processing.

Some of our Users#

Since the initial release as free and open source software, the number of DAMASK users from all over the world is steadily growing. The following institutions have used DAMASK for their research.

Recommended Projects#

DAMASK is best used in conjunction with other software for microstructure generation and data analysis. The following tools are either integrated into DAMASK or can easily be used together with it.